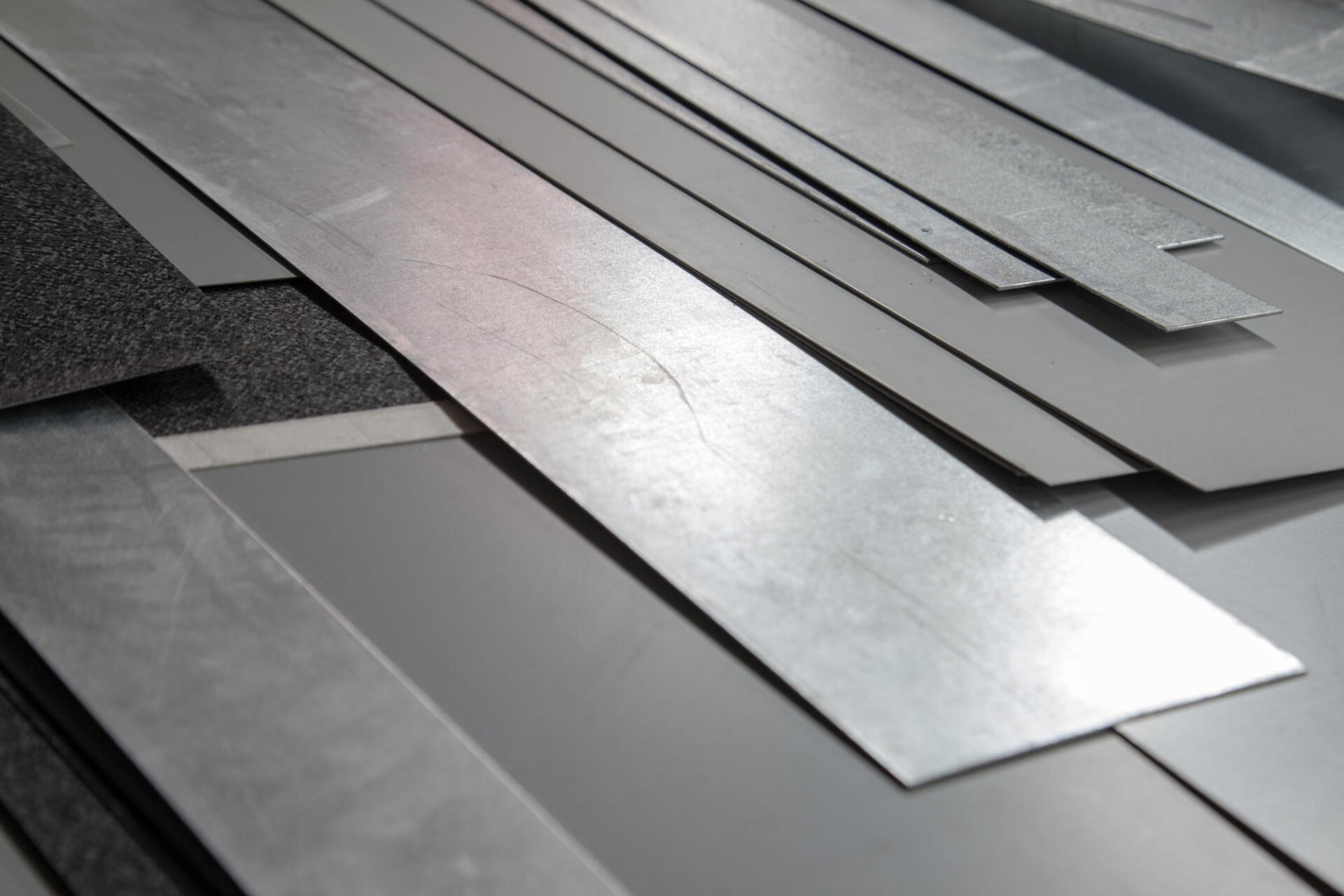

Sheet metal grinding

Sheet metal grinding, with the help of modern machines, is indispensable for professional processing and high-quality design of workpieces.

The purposes of grinding are extremely diverse. Depending on further processing, area of application and composition of the material, sheet metal grinding fulfills various tasks within its higher context.

As a market-leading manufacturer of grinding machines and grinding systems of all kinds, LOESER has been producing solutions for processing metals and numerous other materials for decades. Our constant pursuit of innovation produces state-of-the-art technology that brings numerous benefits in practice and revolutionizes the grinding machine market.

LOESER's modular machine concept enables tailor-made solutions for your company that nevertheless meet the quality of proven series production at the highest level in every respect.

Sheet metal grinding: Applications

An attractive surface finish is crucial for numerous products, as sheet metal parts are often found, for example, as cladding – clearly visible to the customer – on the exteriors of various devices.

A noble aesthetic, which can be achieved by LOESER's modular machine systems in time-efficient work steps, contributes significantly to the value and pleasant feel of a product.

Machines from LOESER: Revolution in sheet metal grinding

Our solutions in the field of sheet metal grinding are multifunctional and can be adapted at a low level to all the needs you encounter in your plant or company.

The modularity of our machines is emblematic of

customer-friendly technologies that focus on supporting your operations. In doing so, we combine technical know-how with practicality in a unique way.

In everyday work, this manifests itself in reduced space requirements, as several work steps can be carried out on the spot thanks to the various attachments. On the other hand, our innovative machine designs result in time and cost advantages, because adaptable removal rates with coarser or finer abrasives as well as almost tolerance-free surface finishes can be achieved in just a few steps with the same equipment.

LOESER offers the intelligent

way to revolutionize sheet metal grinding in your company. You can rely on references from a wide range of industries. Thanks to this wealth of experience and our successful commitment to grinding technology at the cutting edge, we are your ideal partner for customized solutions in series production.