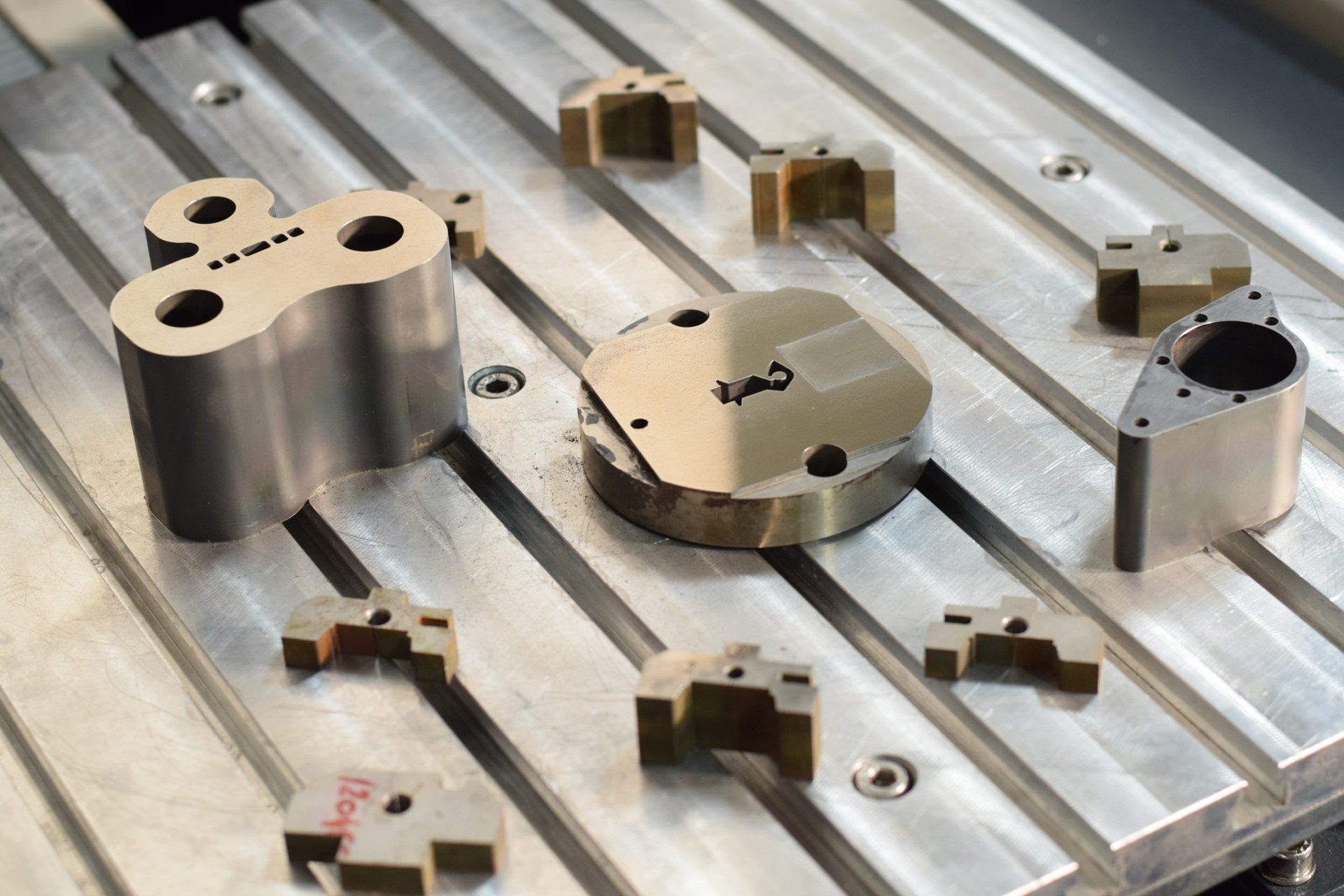

Edge deburring – precision solutions for clean edges

With our solutions for edge deburring, you will be able to remove edges from workpieces. In the manufacturing process, the unwanted material build-up is caused by various work steps:

- punching of flat parts

- laser cutting

- drilling

- milling

To ensure that components are safe to handle later on, precise edge deburring is required. Our machine attachments and systems are designed for this particular purpose.

Our unique modular system enables numerous work steps to be carried out on just one machine. Especially smaller companies that manufacture complex metal parts in-house benefit from our innovative modular principle.

We also offer

solutions for deburring large quantities of parts with our industrial systems. Precision and mechanical innovation are our trademarks.

Edge deburring – modern processes

For edge deburring, our machines offer a fully automatic machining process. This offers numerous advantages:

Exact deburring at all times: workpieces are always deburred to a consistent quality. The tolerance values are very low (up to 0.02 mm). This is essential for further processing in machine-based high-tech environments.

Innovative and user-friendly – edge deburring from LOESER

At LOESER we follow the path of continuous product and process optimisation. Research and industry value our company since innovation and future viability are deeply rooted in our DNA.

In the case of edge deburring, it is demonstrated by the variety of ways in which our systems can respond individually to the requirements of various workpieces. Removal rate, abrasives, feed rate or coarseness – all these parameters can be precisely adjusted to individual needs.

This makes our machines into user-friendly and practical companions for the successful work of your company.