Sheet metal deburring

For sheet metal deburring, LOESER develops user-friendly technologies for small businesses and industrial companies. We realize solutions for sheet metal deburring by means of flexible machine systems, which offer you numerous advantages over conventional machines.

Precision and innovation of our company enable precisely machined workpieces according to the highest quality standards. This is one of the reasons why our systems have established themselves as indispensable supporters in numerous industries.

A fully automatic work process assures you of reliable, consistent quality in sheet metal deburring. Burrs that remain after components have been punched or drilled are removed without tolerance.

Our systems ensure that results in the production of precision parts are in line with requirements. At the same time, processing times are effectively compressed thanks to the automated deburring of workpieces, which ultimately leads to cost savings.

Our products cover sheet metal deburring of both flat parts and round material. Precisely tuned process parameters contribute to an application-specific deburring process. At LOESER, we are well known for the ability to tailor our machines to your application.

Solutions for sheet metal deburring

Our solutions are based on a modular machine system that gives you the greatest possible flexibility in your business. Systems can be precisely adapted to your production processes.

Due to the diverse requirements in the different industries, the modular system is the contemporary answer in sheet metal deburring and other processing steps.

Practice-oriented technology for sheet metal deburring

Our company's solutions are focused on the needs of our customers from a wide range of application areas. Since sheet metal deburring in practice is part of a higher-level, multi-layered work process, the modularity of the modular principle pays off.

Depending on the application,

LOESER's technology allows you to individually select the appropriate tools and attachments for your company. In addition to deburring sheet metal, it is also possible to process its surface according to specified roughness values with our machine systems.

Our processes for sheet metal deburring include

the processing of stamped and milled parts as well as bars and drilled tubes. For the deburring of rims we offer an unique series of machines. This adaptability to real needs, coupled with excellence and professionalism, makes us the world leader in rim deburring. Worldwide, 80% of all rims are deburred and prepared for painting on machine systems from LOESER.

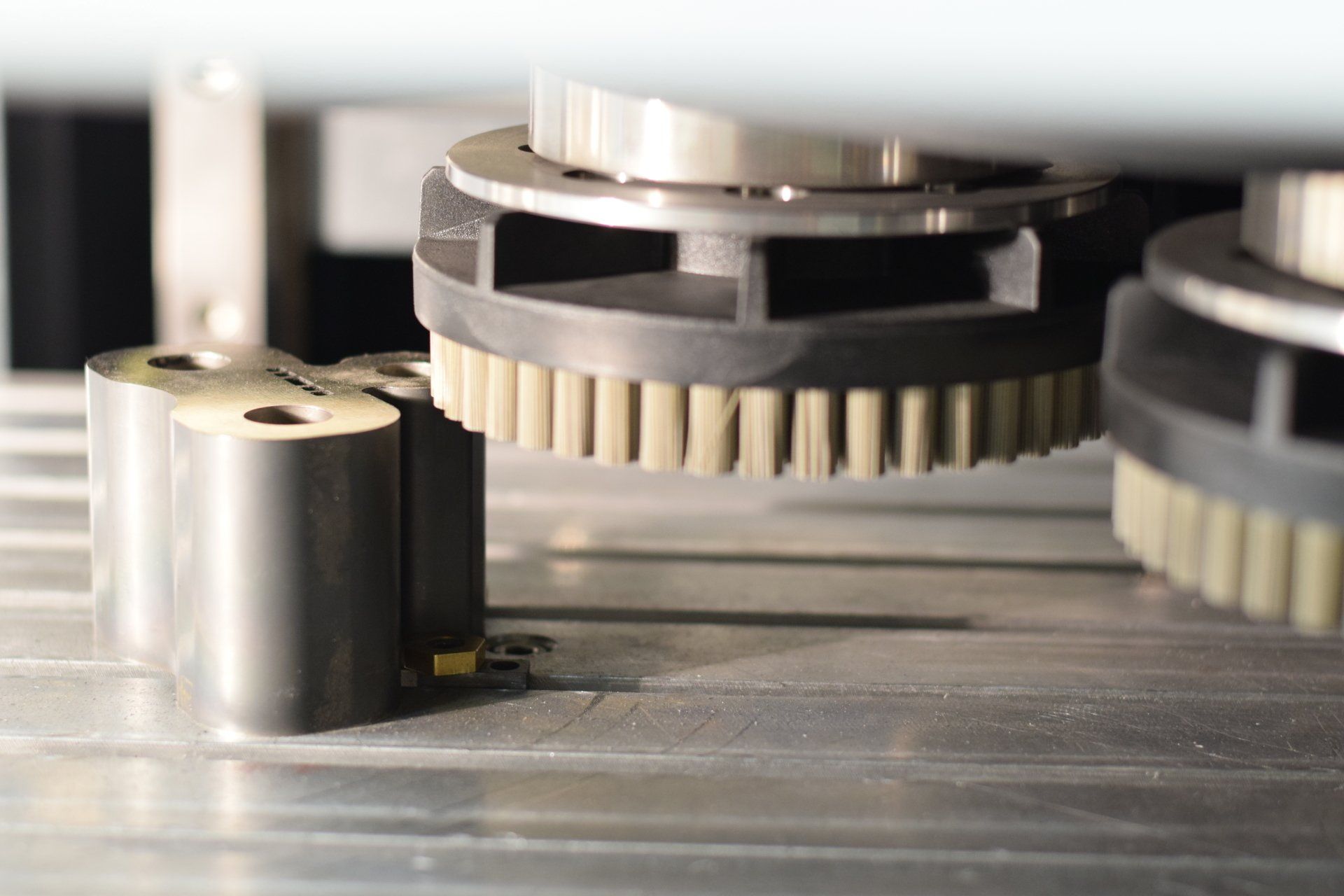

Our machine for sheet metal deburring of various workpieces operates with powerful planetary heads and thus achieves incomparable precision at a width of up to 500 mm. We realize your technology in individual coordination with the production processes and prerequisites in your company.

With

the modular systems from our company, we ensure the success of your production projects – regardless of which industry you belong to.